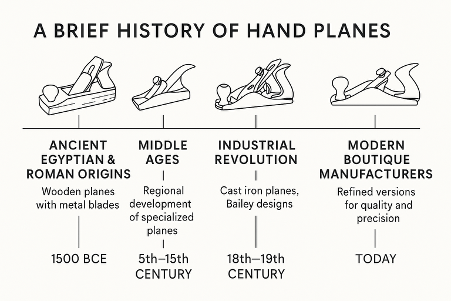

2. 🔨 The Fascinating History of Woodworking Hand Planes: From Ancient Beginnings to Modern Mastery

2.1 The Dawn of the Plane — Ancient Origins

Imagine this: thousands of years ago, long before power tools or even steel, early humans needed to smooth wooden surfaces for everything from shelter walls to simple furniture. The very first “planes” were probably crude wooden blocks with sharp stones or flakes of flint embedded as blades.

- Egyptian ingenuity: Archaeologists have uncovered wooden hand planes dating back to 1500 BCE in Ancient Egypt. These were simple wooden bodies with metal blades, used to craft furniture and decorate tombs.

- The Romans also documented and improved planes, with some examples preserved in ruins and museums. Their designs often included bronze or iron blades.

2.2 The Middle Ages — Woodworking Evolves

Fast forward to Medieval Europe, where the hand plane began its journey from rough wood-and-stone to something closer to what we recognize today:

- Most planes were still all wood, often with a wedged iron blade set into a solid wooden body.

- Skilled craftsmen began shaping more specialized planes for joinery, molding, and other detailed work.

- Planemakers were local artisans, and tools varied widely by region and trade guild.

Fun fact: Early planes sometimes had decorative carvings on the sides—a craftsman’s signature or good luck charm!

2.3 The Industrial Revolution — Iron and Steel Transform Woodworking

The big game-changer came in the 18th and 19th centuries with the rise of iron-bodied planes.

- Around the 1800s, inventors started making cast iron planes with precision-machined parts. This meant:

- Better durability

- Easier blade adjustments

- More consistent flatness of the sole

- Enter Leonard Bailey, whose patented innovations in the mid-19th century formed the basis of the Stanley Bailey system, introduced by the Stanley Rule & Level Company.

- The Bailey design standardized plane sizes, introduced screw adjustments, and allowed for interchangeable parts.

- This system remains the backbone of most metal bench planes today.

Stanley planes became so dominant that “Stanley plane” became almost synonymous with hand planes in North America!

2.3.1 The First U.S. Patents for Metal Hand‑Planes — Innovations That Changed Woodworking

✨ Why Patent History Matters

These early patents mark the transition from hand-crafted, wooden planes to mass-produced, adjustable, metal-bodied planes. They laid the groundwork for the tools we still use today.

🥇 The Very First U.S. Patents – Mid‑19th Century Breakthroughs

🔧 Seth Howes — U.S. Patent No. 37,694 (185 ?)

- Inventor Seth Howes of South Chatham, Massachusetts, proposed a wooden plane with metal components—including an adjustable cap mechanism that allowed simple, secure adjustment of the blade depth and firm retention, while still accommodating wear on the sole by re-adjusting the cap.

This early hybrid design foreshadowed true metal-bodied planes. Sources: working by hand; Project Gutenberg

🔧 Thomas Worrall — U.S. Patent No. 17,657

- Issued around the same era, Worrall’s patent shared a similar principle—combining wood and metal parts for improved blade adjustment. Project Gutenberg

🏗️ Leonard Bailey: The Father of the Cast-Iron Plane

Leonard C. Bailey is the most influential inventor from this era. His patents enabled the development of today’s metal-bodied bench planes.

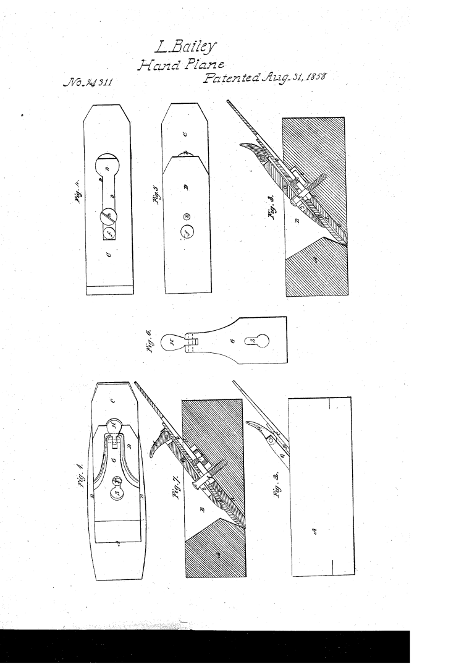

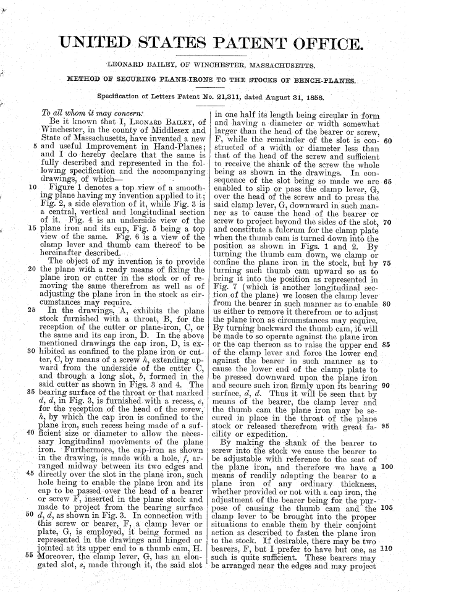

📜 Patent US21311A (August 31, 1858)

- Titled “Method of Securing Plane‑Irons to the Stocks of Bench‑Planes”, this patent introduced a system using a cap‑iron, lever clamp, and nut for precise positioning and securing of the blade—and made possible both lateral and depth adjustment over time, maintaining proper alignment even after resharpening. Method of securing plane-irons to the stocks of bench-planes

📜 Patent US67,398 (August 6, 1867)

- Titled “Improvements in Bench‑Planes”, Bailey addressed blade chatter that was common when using thin plane irons. He invented an auxiliary bend in the chip breaker (cap iron) so that pressure is applied at three points—heel, toe, and mid-section—stabilizing the blade and allowing the use of thinner, cost-effective blades with less chatter. No-72443 – Improvements in Bench‑Planes

📜 Patent US189,415 (April 10, 1877)

- This patent focused on a smoother screw-based depth-adjusting mechanism that used gears and cams for precise, consistent control of blade projection. An improvement over earlier designs, it allowed users to set depth accurately with minimal motion. handplanepatents.com

📜 Patent US196,068 (October 16, 1877)

- Here, Bailey introduced a simplified yet effective system: a cast-metal body with concaved sides for grip, support lugs to lock the iron in place, and a rotating nut bearing directly on the iron—eliminating the need for a cap plate entirely in his configuration, and enabling solid blade retention via three contact points. US196068A

🧾 Summary Table: Landmark Patents

| Year | Patent No. | Inventor | Innovation Focus |

| ~1850s | 37,694 | Seth Howes | Wooden plane with metal cap/adjustment for blade depth |

| ~1850s | 17,657 | Thomas Worrall | Similar wood-metal hybrid design |

| 1858 | 21,311 | Leonard Bailey | Lever clamp and capiron system for securing and adjusting blade |

| 1867 | 67,398 | Leonard Bailey | Auxiliary bend in cap iron to reduce chatter using thin blades |

| 1877 | 189,415 | Leonard Bailey | Precision cam-and-screw depth adjuster for accurate blade projection |

| 1877 | 196,068 | Leonard Bailey | Cast-iron body with lugs and nut-based iron retention, no cap required |

🧠 Legacy & Influence

Leonard Bailey’s designs—especially from the patents above—were acquired and popularized by Stanley Rule & Level Company, forming the Bailey system still used in modern Stanley metal planes. His ideas also influenced later inventors like Justus Traut, Henry Clark, and George Varren, and the system became the reference standard for bench plane functionality. Plane (tool) Wikipedia

🧩 Fun Thought Experiment

Picture yourself in Winchester, Massachusetts in 1858, holding a wooden plane. Bailey hands you a shiny new cast-iron body with a lever-adjustment screw. You flex the cap iron and realize you can fine-tune the blade without wedging. Then he shows his second design: a cap iron bent in three places to eliminate chatter—and you understand how this is going to change woodworking forever.

2.4 The 20th Century — Refinement and Decline

With the advent of power tools in the 20th century, hand planes were no longer the only tool in the shed. But they didn’t disappear:

- Hand planes shifted from daily necessity to a specialist’s tool, prized for fine work, touch-up, and finish sanding alternatives.

- Manufacturers like Stanley, Record (UK), WoodRiver, and others produced a wide variety of planes, including cheaper models for hobbyists.

- Despite the rise of machines, traditionalists, restorers, and custom furniture makers kept hand planing alive.

2.5 The Modern Revival — Hand Planes Make a Comeback

In the 21st century, hand planes have experienced a renaissance:

- Boutique toolmakers like Lie-Nielsen, Veritas, Luban, and Juuma craft premium planes combining classic design with modern materials.

- Woodworkers rediscover the joy, control, and beauty of hand planing.

- Online communities and videos have fueled the learning curve, making hand plane mastery accessible to new generations.

2.6 Timeline Recap

| Era | Key Development |

| Ancient Egypt (1500 BCE) | Wooden planes with metal blades appear |

| Roman Period | Bronze and iron blades, refined shaping |

| Medieval Europe | All-wood planes with wedged blades; regional styles flourish |

| Industrial Revolution | Cast iron bodies, screw adjustments, Stanley Bailey system |

| 20th Century | Power tools rise; hand planes become specialist tools |

| 21st Century | Boutique makers and hobbyists revive hand planes |