5. Choosing the Right Plane for Your Needs 🛠️

Selecting the right handplane depends on your woodworking goals, skill level, and the tasks at hand. Drawing from years of experience, this section helps you tailor your toolkit effectively.

🎯 5.1 Beginner’s Essential Toolkit

Start here if you’re new to hand tools:

- Stanley No. 5 Jack Plane — widely available and ideal for flattening rough stock and general use. Vintage versions can be tuned to perfection and are beginner-friendly investments.Mastering wood planes, Lost Art Press; Handplanes (Lost Art Press)

- Low-Angle Block Plane (~60‑½) — excellent for trimming end grain, chamfers, and fiddly edge work; beginner-friendly with minimal setup.Sawmill Creek Woodworking Community

These two planes form a powerful duo—comprehensive for basic planing, flexible in function, and not overwhelming to manage.Reddit; The Renaissance Woodworker

🧰 5.2 Intermediate Upgrades

As you gain experience and expand your projects, consider:

- Jointer Plane (No. 7 or No. 8) or Fore Plane (#6) — essential for working on larger panels or long edges. Ideal for leveling and flattening before smoothing. Fore plane (Wikipedia)

- Premium Planes from Lie‑Nielsen, Veritas, or Wood River — these offer tighter tolerances, precision setup, and easier initial tuning compared to vintage planes.

Expert tip: Christopher Schwarz (Lost Art Press) notes that a properly set-up Stanley No. 5 often delivers all a beginner needs—and it’s respectful of hands-on learning.

🌟 5.3 Advanced & Specialty Additions

Once you’re comfortable, explore these planes for specific applications:

- Smooth Plane (No. 4 / No. 3) — perfect for final finishing; often set with razor-thin shavings and a tight mouth.The Renaissance Woodworker

- Rabbet (Shoulder) Plane — precise for trimming tenons and rebate joints. Especially useful for fine joinery accuracy.Reddit; Moulding plane (Wikipedia)

- Router Plane — excellent for cleaning up dados or hinge mortises and grooves to consistent depth.

- Combination or Plow Plane — handles multiple profiles, tongues, and grooves with interchangeable bits. A flexible tool for assembly and paneling.

These specialty tools don’t replace core bench planes but greatly enhance your joinery and finishing capabilities.

🤑 5.4 New vs. Vintage: What Should You Choose?

Vintage Stanley Tools

- Pros: Affordable, robust, restorable, often high-quality castings.

- Cons: Require flattening, tuning, and blade sharpening expertise.Lost Art Press

Quality Modern Tools (Lie‑Nielsen, Veritas, Wood River)

- Pros: Factory-flat soles, tight mouths, high-performance steels like A2/O1/PM‑V11, often ready to go.

- Cons: Cost significantly more.

Community Wisdom from Woodworking Forums summarizes it well:

“For less money you can get vintage Stanley planes but will spend more time making them functional. For more money you can buy new… For even more money you can buy a new premium hand plane… these are the pinnacle of high quality but you will pay for it.”Reddit

🔧 5.5 Matching Planes to Tasks

| Scenario / Task | Recommended Plane(s) |

| Flatten and rough-shape rough sawn stock | Jack (#5) or Fore (#6) — cambered blade |

| Correct long edges or large flat surfaces | Jointer (#7 or #8) |

| Final finishing surface | Smoother (#4 or #3) — fine mouth, sharp iron |

| Chamfers, edge trimming, end grain cleanup | Low‑angle Block Plane (bevel-up) |

| Tenon shoulders, rebates, tight joinery cuts | Shoulder or Rabbet Plane |

| Grooves, dadoes, mouldings, or profile work | Combination, Plow, Router, or Hollow/Round Plane |

Also: match the size of the plane to the workpiece. A #4 smoother for a tiny box part may be more efficient than a #8 jointer.

⭐ 5.6 Personal Recommendations (from Expert Sources)

- Christopher Schwarz: For a beginner-friendly, lightweight, minimal-fuss jack plane, try the No. 62 jack plane— it skips the frog and lateral adjuster for a clean, simple experience.

✅ Final Checklist Before Buying

- Define your primary woodworking tasks (stock prep, joinery, finish surfaces).

- Choose durable and appropriate size tools that suit your workflow.

- Decide vintage vs modern based on time investment for tuning.

- Learn sharpening first—a well-honed iron is more effective than an expensive tool.

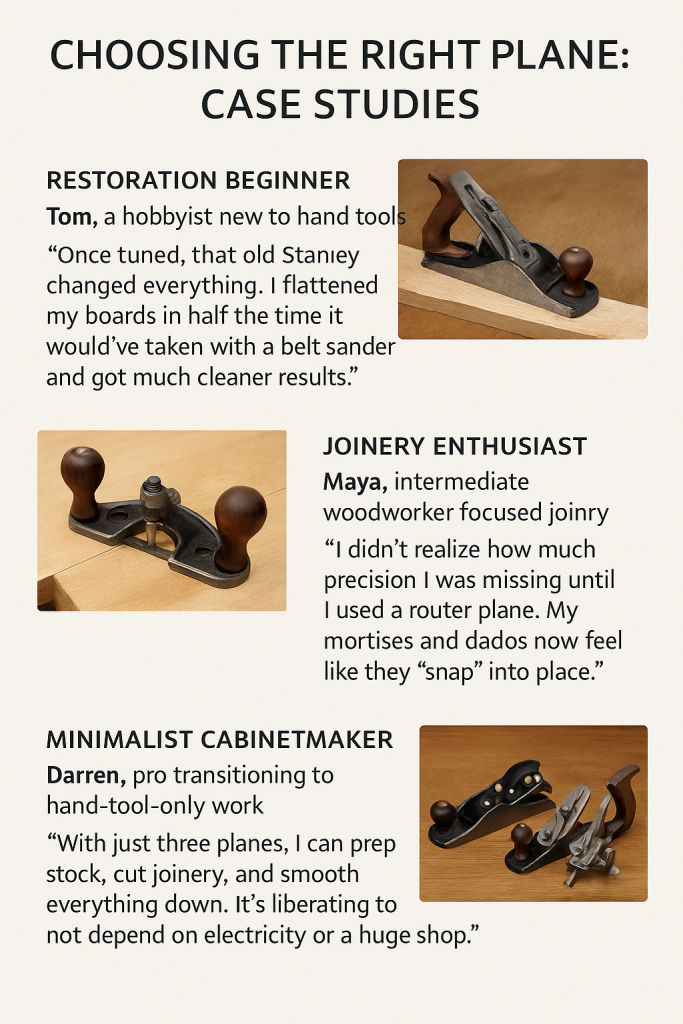

📚 Case Study 1: The Restoration Beginner

User: Tom, a hobbyist in his late 30s starting out with basic furniture projects.

Goal: Build a small side table using reclaimed oak boards.

Initial Problem: Tom bought rough-sawn oak from a salvage yard, but didn’t want to invest in a planer/jointer. He tried sanding the boards flat, but it was slow and uneven.

Solution:

- Bought a vintage Stanley No. 5 jack plane for $35 on eBay.

- Watched YouTube tutorials (e.g., Wood and Shop and Renaissance Woodworker) on how to flatten the sole, sharpen the iron, and set the chipbreaker.

- Learned to camber the blade slightly for aggressive stock removal.

Result:

“Once tuned, that old Stanley changed everything. I flatted my boards in half the time it would’ve taken with a belt sander and got much cleaner results.”

Lessons Learned:

- Restoration teaches valuable tool maintenance skills.

- One versatile jack plane can substitute for several power tools in the beginning.

📚 Case Study 2: The Joinery Enthusiast

User: Maya, an intermediate woodworker focused on joinery—especially through-tenons and dovetails.

Goal: Build a traditional Japanese-style cabinet with frame-and-panel construction and no screws.

Initial Problem: Maya’s joinery looked good “on paper,” but her tenon shoulders were never flush. She used chisels to clean them up but struggled with consistency.

Solution:

- Invested in a Veritas Medium Shoulder Plane to fine-tune tenons and rebates.

- Bought a router plane (also Veritas) to clean up dadoes and hinge mortises.

Result:

“I didn’t realize how much precision I was missing until I used a router plane. My mortises and dados now feel like they ‘snap’ into place.”

Lessons Learned:

- Specialty planes like shoulder and router planes aren’t just “nice to have”—they’re essential for crisp, reliable joinery.

- Flat bottoms and fine adjustability beat chisel guesswork for consistent cuts.

📚 Case Study 3: The Minimalist Cabinetmaker

User: Darren, a professional woodworker aiming for a minimalist, portable hand tool kit.

Goal: Transition from a power tool shop to a hand-tool-only workflow, inspired by historical joinery.

Initial Problem: Wanted to simplify his workflow but couldn’t decide which hand planes were truly essential without duplicating effort.

Solution:

- Consulted resources from Lost Art Press and The English Woodworker.

- Built his core kit around:

- Low-Angle Jack (No. 62) – used for jointing, smoothing, and shooting.

- Block Plane (60-½) – for trimming and chamfering.

- Plow Plane – for grooves and small panel assemblies.

Result:

“With just three planes, I can prep stock, cut joinery, and smooth everything down. It’s liberating to not depend on electricity or a huge shop.”

Lessons Learned:

- Bevel-up jack planes offer immense flexibility with different irons.

- A small, well-thought-out kit can outperform a cluttered bench full of tools.

🧠 Summary Takeaways from the Case Studies:

| Scenario | Plane(s) Used | Key Insight |

| Rough lumber flattening | Vintage Jack Plane (No. 5) | Budget-friendly and extremely versatile |

| Tenon & dado precision | Shoulder Plane + Router Plane | Specialty planes make crisp joinery faster and repeatable |

| Small, minimalist workshop | No. 62 + Block + Plow Plane | Compact bevel-up systems are powerful and adaptable |